Technologies

Best Fast 3D Printers of 2023

Ultrafast 3D printers are here, and we’ve been testing them to see if they’re worth the hype. Turns out they are, so we’ve got the best all lined up for you.

In the age of 3D printing, quality has always been the most important factor. Achieving good quality prints always came at the price of speed, but that was OK because a 14-hour print was still better than the days it would take and the expense it would cost to get something made in a factory.

With the advent of new, fast 3D printers though, we can cut that 14-hour print time to seven hours or less, saving you time and money, and letting your creative juices flow at a much higher rate. If you already own several of the current best 3D printers you may not want to upgrade to a faster printer just yet, and that’s OK. But, if you’re on the lookout for a printer that offers excellent quality and can blow you away with its speed, we have the goods right here.

What’s the best fast 3D printer?

Balancing in that sweet spot between affordability and usability, the P1P from BambuLab is currently the best fast 3D printer to buy. It isn’t the pinnacle of fast printers on the market — that would be its big brother the X1C — but it is significantly cheaper, making it a better value proposition than the X1C.

Fast 3D printers are still relatively new, so this list will update on a regular basis from here on out. Keep your eye out as we add new printers when the testing is finished.

Best fast 3D printers

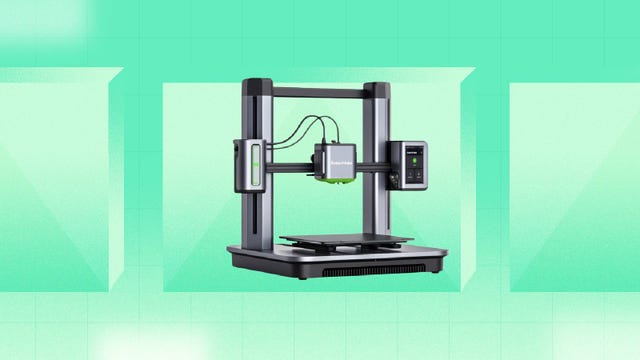

The P1P from Bambu Lab is currently one of the very best 3D printers you can buy. Priced at $699, it isn’t the cheapest printer, but it is incredibly fast and the print quality is consistently excellent. While the P1P is bare-bones on the outside, it does come with a host of advanced features like auto bed leveling, filament runout sensors and power-loss detection. It even has a camera that creates time-lapse videos for social media.

Because Bambu Lab makes the P1P, it’s compatible with the company’s AMS, an extra device that lets you print in more than one color or material. The addition of the AMS makes the P1P almost as versatile as Bambu’s flagship printer, the X1 Carbon, at a significant saving.

Read more: Bambu Lab X1 Carbon vs. Bambu Lab P1P

While I do wish that the P1P had a better LCD, and the SD card that comes with it is shockingly slow (I recommend replacing it immediately), these negatives do not overshadow how excellent this 3D printer is. I use mine every single day and it’s amazing.

While not as fast as the P1P or the X1C, the Kobra 2 is around the same speed as the AnkerMake M5. It will happily produce prints at 250 millimeters per second, though the best quality seems to be hovering around 150mm/s in my testing. It also comes with a filament runout sensor and bed leveling, which works extremely well.

The big selling point for the Kobra 2 though is the price. It has all the advantages of a faster printer with a sub-$300 price tag, which is astonishing. This is my recommendation for any first-time buyer or someone on a budget.

One of the first consumer 3D printers to break the 250mm/s speed barrier, the AnkerMake M5 has recently had a software update to push its speed up to 500mm/s on its ultrafast mode. The M5 uses an AI camera to help you detect issues so you can stop a failing print before you waste a lot of material. The AI is particularly bad, but the camera does give you some fantastic time-lapse videos to share on social media.

Read more: AnkerMake M5 Review

If you’re looking for a fast printer that doesn’t take up a lot of room, this is an excellent beginner’s choice.

Of all the fast 3D printers I’ve tested, the X1 Carbon reigns supreme. In every category I test, it stands out on top. The only thing that keeps it from being my top pick is the cost. This educational bundle, while offering a lot of value, is still $1,599, nearly three times the price of the AnkerMake M5.

The X1C is custom-made for exotic materials that require a hardened nozzle. Things like carbon fiber-infused materials require a stronger nozzle, or they will be worn down very quickly. When you couple that with the lidar bed leveling, AMS color system and an AI camera to spot errors, you have a formidable machine.

Read more: Bambu Lab X1 Carbon vs. Bambu Lab P1P

Fast 3D printers on the way

While these printers look to be in the same ultrafast vein as the others, we have yet to completely test them in the way we would want. Because of that, we are not able to recommend them fully, at least until our full testing is complete.

Right now, the Prusa MK4 is sitting on my workbench, churning out excellent prints by the bucketful. I’m still not quite finished with the full review, but so far, the MK4 is living up to Prusa’s excellent reputation. Almost every aspect of the MK4 is an upgrade to the MK3S Plus, with a new removable nozzle setup, a new extruder, and an automatic z-height adjustment system that promises «perfect first layers every time.»

Testing isn’t quite finished yet, but Prusa has a great track record, so this isn’t likely to be a bad machine.

Read more: Prusa MK4 Follows Up Best in the Business

The K1 and K1 Max are Creality’s new flagship 3D printers. The company is promising 600mm/s — the fastest speed from any printer so far — at a price that’s hard to believe: $600 for the K1 and $999 for the K1 Max, a printer with a larger build volume, seems too good to be true.

We haven’t got one of these in for testing yet — no one has — but I’m excited to try it out and see how it stacks up against the more expensive competition. What’s interesting is the full enclosure and lidar bed leveling that come as standard on the K1. That’s something you would only normally find on a much more expensive machine.

Read more: Creality K1 Is Its Answer to Bambu and Prusa

More on 3D printing

How we test

Testing 3D printers is an in-depth process. Printers often don’t use the same materials, or even the same process to create models. I test SLA, 3D printers that use resin and light to print, and FDM, printers that melt plastic onto a plate. Each has a unique methodology. Core qualifiers I look at include:

- Hardware quality

- Ease of setup

- Bundled software

- Appearance and accuracy of prints

- Repairability

- Company and community support

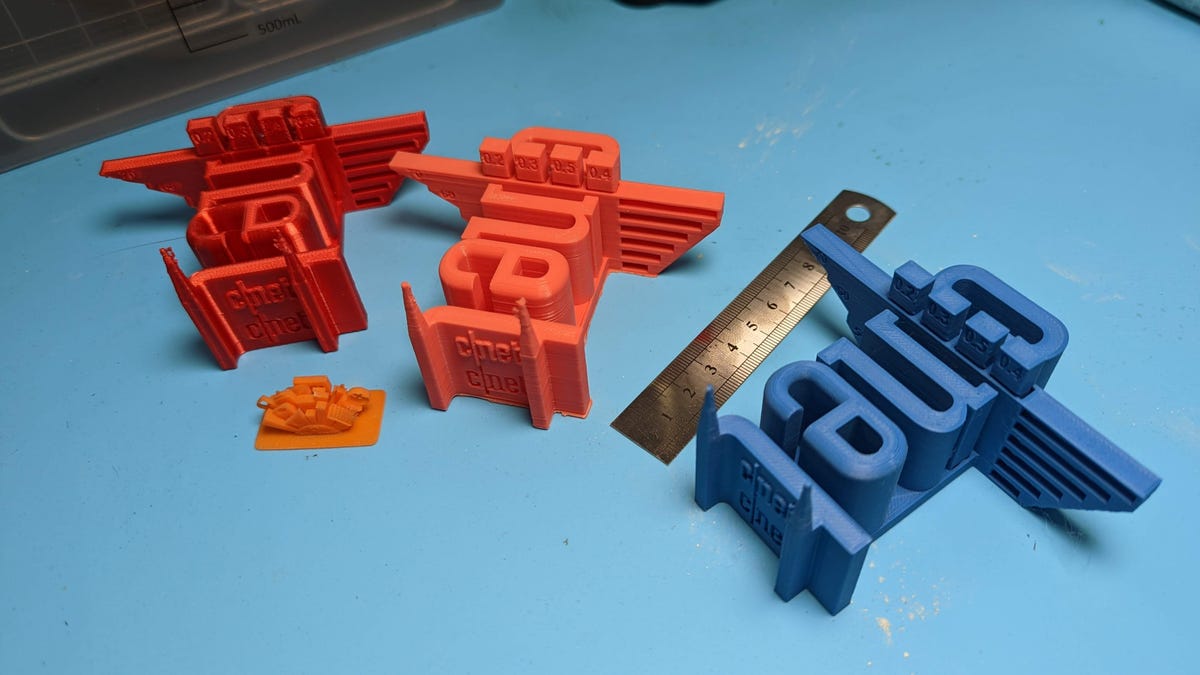

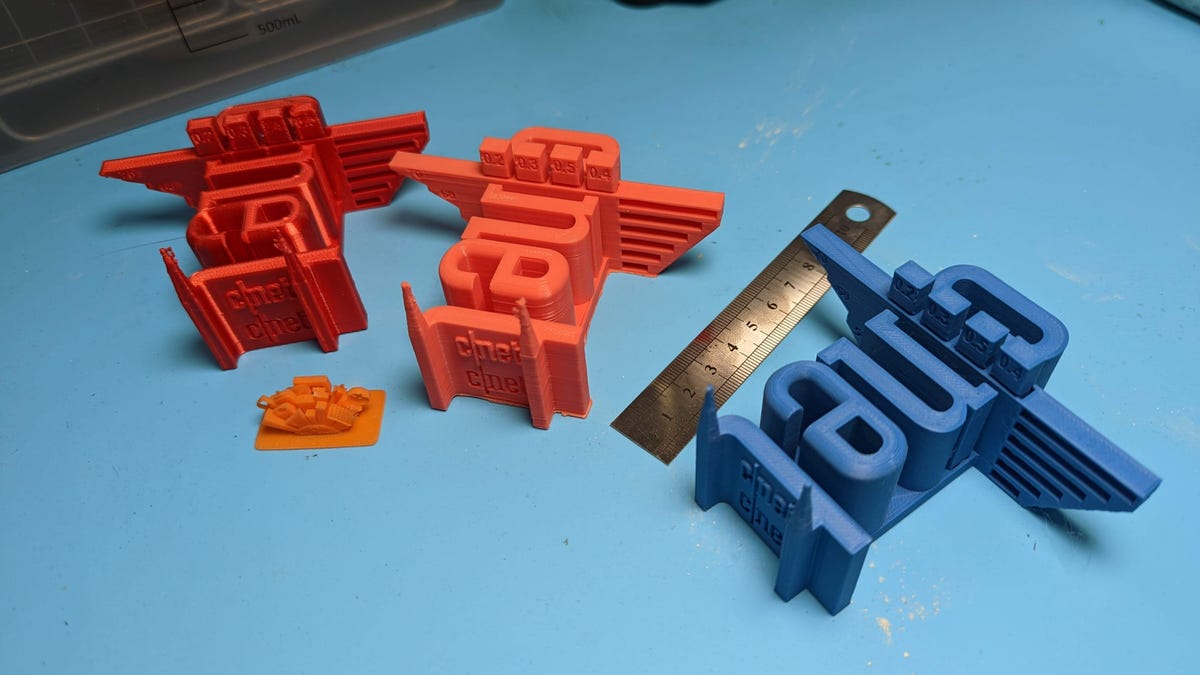

A key test print, representing the (now old) CNET logo, is used to assess how a printer bridges gaps, creates accurate shapes and deals with overhangs. It even has little towers to help measure how well the 3D printer deals with temperature ranges.

When testing speed we slice the model using the standard slicer the machine is shipped with on its standard settings then compare the real-world duration of the print to the statement completion time on the slicer. 3D printers often use different slicers, and those slicers can vary wildly on what they believe the completion time to be.

We then use PrusaSlicer to determine how much material the print should use and divide that number by the real-world time it took to print to give us a more accurate number for the speed in millimeters per second (mm/s) the printer can run at.

Many other anecdotal test prints, using different 3D models, are also run on each printer to test the longevity of the parts and how well the machine copes with various shapes.

For the other criteria, I research the company to see how well it responds to support queries from customers and how easy it is to order replacement parts and install them yourself. Printers that come only semi-assembled as kits are judged by how long, and how difficult, the assembly process is.

3D printing FAQ

What material should I use to print with?

Most home 3D printers use PLA or ABS plastic. Professional printers can use all sorts of materials, from metal to organic filament. Some printers use a liquid resin, which is much more difficult to handle. As a beginner, use PLA. It’s nontoxic, made mostly of cornstarch and sugarcane, handles easily and is inexpensive. However, it’s more sensitive to heat, so don’t leave your 3D prints on the dashboard of a car on a hot day.

Which brand of PLA is best?

What brand is best will depend on the job you’re trying to do. If you want to print something that looks amazing with no post-processing, Polylite from Polymaker is a great choice with a large range of colors and finishes.

If you’re printing something that’s going to be sanded and painted, like cosplay armor, I would go with MatterHackers Build PLA. It’s easy to sand, holds paint well and is cheaper the more you buy.

What settings should I use?

Most 3D printers include or link to recommended software, which can handle converting 3D STL or other files into formats supported by the printer. Stick with the suggested presets to start, with one exception. I’ve started adding a raft, or bottom layer of filament, to nearly everything I print. It has cut down dramatically on prints that don’t adhere to the bed properly, which is a common issue. If you continue to have problems, rub a standard glue stick on the print bed right before printing.

What are supports?

Your 3D models probably need some help to print properly, as these printers don’t do well with big overhangs — for example, an arm sticking out from a figure. Your 3D printer software can usually automatically calculate and add supports, meaning little stands that hold up all those sticking-out parts of the model. After the print is done, and file down any nubs or rough edges with hobby files.

Where do I find things to print?

Thingiverse.com is a huge online repository of 3D files for anything and everything you can think of. Pokemon chess set? It’s there. Dyson vacuum wall mount? You bet.

You can also try Printables.com for the latest models. Printables uses a gamified reward system that can earn you free filament just for uploading pictures of the things you make.

When you’re ready to create your own designs, there are a ton of software packages to choose from, but it’s easiest to start with the browser-based free TinkerCad app from Autodesk.